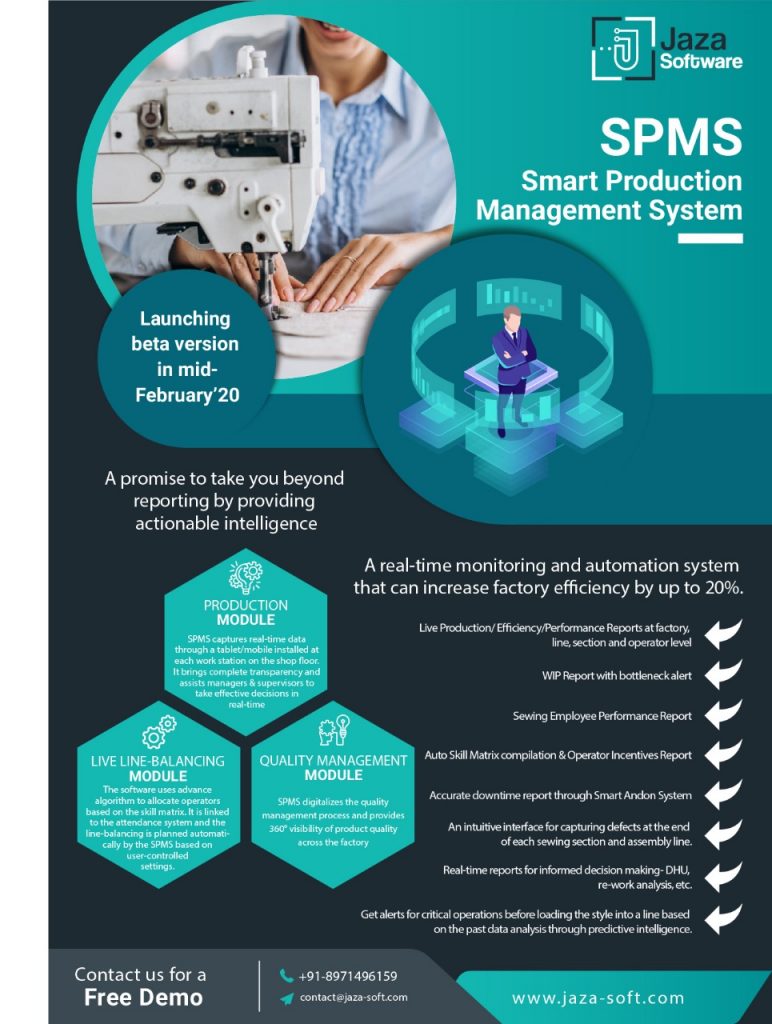

SPMS captures real-time data through a tablet/mobile installed at each work station on the shopfloor. It brings complete transparency and assists managers and supervisors to take decisions in real-time. The software uses advance algorithm to allocate operators based on the skill matrix.

It is linked to the attendance system and the line-balancing is planned automatically by the SPMS based on user-controlled settings. “A real-time monitoring and automation system that can increase factory efficiency by up to 20%,” said Md Jawed Akthar, Co-founder & CEO, Jaza Software.

It can provide WIP Report with bottleneck alert; sewing employee performance report; auto skill matrix compilation and Operator Incentives Report; accurate downtime report through Smart Andon System; an intuitive interface for capturing defects at the end of each sewing section and assembly line.

It also gives alerts for critical operations before loading the style into a line based on the past data analysis through predictive intelligence.