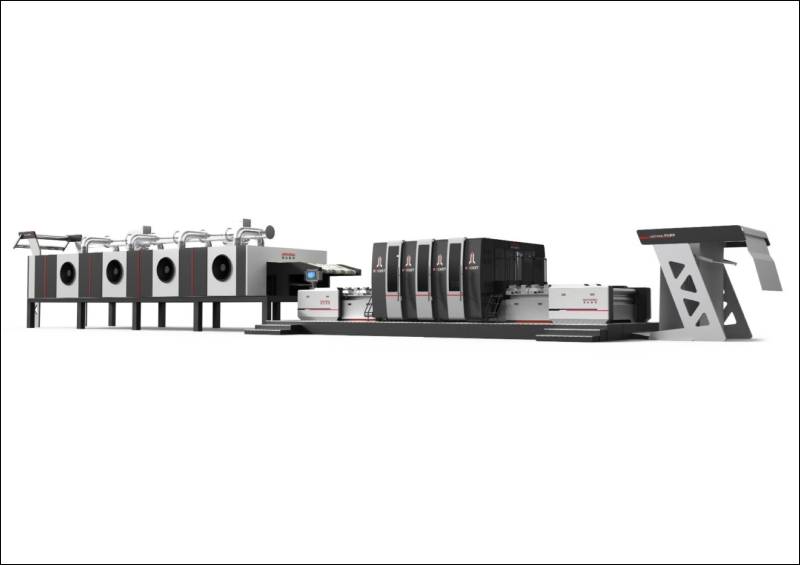

Orange O Tec introduces ‘Rocket’, a revolutionary hybrid single-pass digital textile printing machine, to the Indian market. Designed for unmatched speed, precision, and sustainability, Rocket delivers up to 60,000 linear metres per day, redefining performance benchmarks for the textile industry.

Versatile, High-Speed Printing Power

Engineered to meet the evolving demands of India, Bangladesh, and China, Rocket supports pigment, reactive, and disperse inks—making it ideal for both mass production and bespoke applications.

End-to-End Automation

Rocket offers a fully integrated workflow from fabric feeding to drying and collection, requiring minimal manual intervention. Key components include:

-

Fabric Feeding & Belt Guiding Systems

-

Inline Coating & Online Fabric Sizing

-

High-Speed Inkjet Module

-

Controlled Drying Chamber

-

Smart Collection Unit

Ink & Fabric Compatibility

Rocket ensures high-quality output on a wide range of substrates, including:

-

Natural fibers: Cotton, viscose, linen, hemp

-

Blends: Cotton-polyester, viscose mixes

-

Synthetics: Polyester-rich fabrics (with disperse inks)

Sustainability Through Pigment Inks

With no need for post-processing, pigment printing with Rocket saves water and energy while delivering brilliant, durable prints. Its eco-advantage includes:

-

50% less paste use

-

15% brighter colours

-

Up to 15% ink savings

-

Lower nitrogen emissions

Hybrid Innovation with Added Value

Rocket’s hybrid platform combines digital inkjet with rotary screen features, enabling effects like:

-

Metallic foils (gold/silver)

-

Pearlescent and glue pastes

-

Colour-shifting inks

-

Embossed/textured finishes

Proven Performance Across Asia

-

China: Over 25 Rocket units installed; major players like Shaoxing Shengxin Printing use six machines for 3,00,000+ sqm/day production.

-

Bangladesh: Strong interest following DTG exhibition debut; 9 units already in the pipeline.

-

India: Anticipated arrival in Surat, Tirupur, and other hubs—aligning with ESG goals and premium export ambitions.

Built for a Greener Future

Sustainability is at the core of Rocket’s design:

-

Low-temp drying for energy savings

-

Odour control & disinfection for hygienic output

-

Compact footprint for reduced operational costs

Rocket: The Future of Digital Textile Printing

Whether you’re printing natural fibres with pigment, blends with reactive, or synthetics with disperse inks, Rocket is your future-ready platform for speed, flexibility, and sustainability in textile manufacturing.