Garments and apparel industry always look for better benchmarks in terms of productivity and quality. With all buyers putting in research for better quality price ratios, the five pocket style pants, denim and no denim categories have become very competitive. Keeping this scenario in mind, Giorgio Morandin, the Sales & Marketing Manager SIP ITALY, averred, “We want to be a one-step solution provider; our customer daily needs sewing quality solution, new production processes, reduction in production cost, ideas to reduce handling, different layouts and more. For this reason, we want to be a technical partner for a customer and not a simple machinery supplier. This is our goal and this is one of the pillars of our success, especially in the Far East.”

Download Perfect Sourcing News App for Latest Business of Fashion News.

The company has set up turnkey projects on the subcontinent, in Pakistan, India and Bangladesh. SIP ITALY is a division of Tor.Mec Ambrosi S.r.l., specialising in development and production of automatic units. With 30 years of expert experience, the two production plants of the unit, located in Verona, Italy are ISO 9001 quality certificated for the entire vertical production process and management.

The company has a wide range of automatic units with common electronic hardware, standard sewing heads, standard displays and menu software. Giorgio is hopeful that the leaders of the apparel industry will spend some time to learn at least 50 per cent of the technical details of automatic sewing machines as no matter what brand they are going for, it is always a matter of high investment and concern. He advises that in the matter of a new project evaluation or a simple single unit purchase, customers should focus on enlarged analyses, thinking on medium to long terms and taking the time to evaluate the technical details in considerable detail.

Giorgio commented, “The supply chain is a value of a company. In our case we are proud and we emphasise how A class Japanese partners such as Brother Industries, Pegasus and Seiko are our company technical partners.”

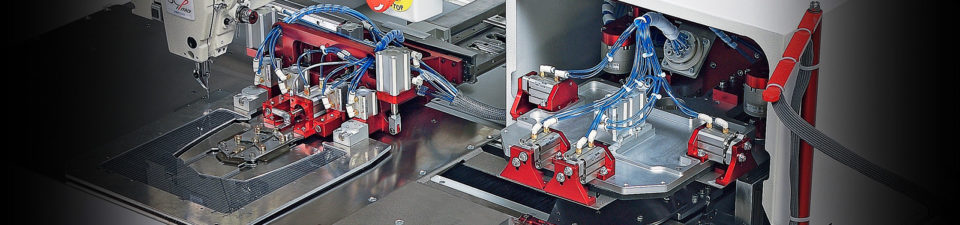

Giorgio shared its product range for denim which comprises of model PS342FG1SIP.V2, LS915H-SIP and FOA261M-SIP. The PS342FG1SIP.V2 is a fully automatic pocket setter unit that can fold and attach on the same workstation. Cold folding device is a unique solution for stretch denim fabric; it does not require extra workers and helpers to manage the pocket pressing unit, which saves space, energy and general running cost. The machine uses original Brother sewing head, standard X-Y technology, hardware & software by Brother Japan, which are the same as other Brother pattern sewer units; also, it has an automatic device for quick pocket jig change and digital sewing thread tension. Output parameters are: complete cycle time of 10 seconds; regular pocket size; average production of 120 pairs per working hour or 960 pairs / eight working hours. The LS915H-SIP is an automatic belt loop setter unit which has an automatic programmable belt loop setter unit for cutting, folding and attaching the patch loop in one operation. The user is able to make all kinds of bar-tack sewing designs on the board using the console or a PC. One complete cycle time is 11 seconds in which 5 loops is made so average production with 5 loops is 200 pairs per working hour, i.e., 1,500-1,700 pairs / eight working hours.

FOA261M-SIP is the feed of the arm unit, with three needles, chain stitch and special design for lap felling and/or double-lap seaming like yoke sewing, back seat, in-seam and side-seam operations for jeans, casual trousers, working clothes and denims in general. The unit is also utilised for top stitch operations.

2 comments

Supplier nearest you Ethiopia and can facilitate LC ( letter of credit ) pleas

Supplier nearest yo Ethiopia and who can facilitate LC ( letter of credit ) pleas