Mumbai-based Weaving Vibes, with a legacy spanning five decades in textile manufacturing, is at the forefront of innovation, creating sustainable, biodegradable, 100% natural plant-based fabrics. In a conversation with Shripat Jagirdar, Founder of Weaving Vibes, TEAM PERFECT SOURCING explores the company’s ideology and its niche in sustainable fabrics through regular innovation.

The dream of yarns, weaves, and fabrics was a vision Shripat Jagirdar’s late grandfather had, creating a legacy for the family to inherit and dream ahead from. In fact, the first weave of Weaving Vibes’ textile story was woven four decades ago.

Having pioneered the power loom woven cotton and all its blends in India, it was time to weave a new story for the next generation. The company’s vision is to revolutionise the textile industry by prioritising sustainability and innovation, aiming to create a future where textiles are not only beautiful and functional but also kind to the environment.

“We aspires to inspire the next generation of textile enthusiasts and set new standards in quality and sustainability,” said Shripat. He further added, “The idea of creating this company was to merge rich heritage in textile manufacturing with modern, sustainable practices to offer something truly unique and forward-thinking,” he added.

The company offers custom designs and advanced value additions such as AZO-free digital printing, foil printing, natural dyeing, and eco-printing.

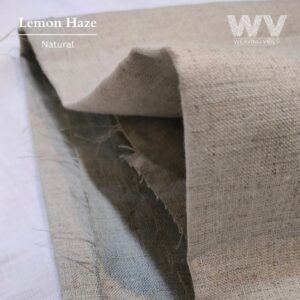

Among Weaving Vibes’ unique selling products are 100% Hemp Fabric, which is highly sustainable, durable, and biodegradable. Known for its strength, breathability, and antibacterial properties, hemp fabric is ideal for various applications, from apparel to home textiles.

Additionally, their Hemp-Cotton Blends combine the best of both fibers, offering enhanced comfort, softness, and durability.

Another interesting product that the company offers is festive foil prints on hemp fabrics that brings a touch of luxury and elegance, perfect for special occasions with unique, eye-catching designs and no minimum order quantity.

Sustainable printing methods create eco-prints on hemp-cotton blends, featuring natural motifs like silver oak leaves, which are both beautiful and environmentally friendly. Digital printing capabilities allow for highly detailed and vibrant designs on hemp fabrics, ensuring precision and creativity for bespoke design needs. Newly developed waffle weave fabrics are perfect for creating textured, absorbent, and soft textiles, ideal for towels, robes, and loungewear.

“As exclusive sellers of EU hemp yarns in India, we also provide high-quality, sustainable yarns that are perfect for knitting, weaving, and other textile applications,” he informs.

Efficient production processes are followed so that the supply chain management cost remain competitive.

On being asked how the company manages quantity he replies. “Managing quantities in sustainable fabrics involves a state-of-the-art facility that allows for quick adjustment of production volumes based on demand fluctuations, reducing waste and ensuring efficient use of resources.”

Weaving Vibes offers no MOQ options, enabling customers to order small quantities as needed, reducing excess inventory and supporting sustainable consumption practices. A lean and responsive supply chain ensures timely procurement of raw materials and efficient production schedules, aligning with sustainability goals. Sourcing raw materials in bulk from responsible suppliers reduces transportation emissions and costs, allowing for sustainable quantity management.

Technologically, Weaving Vibes uses state-of-the-art advanced auto-looms, including Airjet machines, to ensure precise, high-quality weaving. These machines enhance efficiency and consistency in fabric production. For dyeing and digital printing, the company prioritizes sustainability by using AZO-free dyes, ensuring fabrics are safe for both the environment and consumers. Collaborations with various clusters across the country is done to implement eco-printing techniques, using natural dyes and sustainable methods to create unique, environmentally friendly prints.

On being asked what is in trend these days, he replied. “In the export market, there is significant demand for sustainable apparel fabrics, particularly hemp and hemp blends, valued for their eco-friendliness and durability. Organic cotton blends are also popular due to their comfort and sustainability.”

According to him home textiles such as waffle weave fabrics are sought after for towels, robes, and home accessories because of their absorbency and texture. Eco-printed linens, featuring unique natural dyes, appeal to global consumers interested in eco-friendly home decor. Specialty prints, including digital and foil prints, are also in high demand for high-end fashion and boutique markets, offering custom and striking designs.

In the domestic market, festive and traditional fabrics like foil prints on hemp are popular for their luxurious and vibrant appeal, especially during festive seasons. In the home and lifestyle segment, waffle weave towels and bathrobes are in growing demand due to their high quality and sustainability.

Talking about some of the challenges being faced while manufacturing and marketing sustainable fabrics in India Shripat shared that the higher cost of sustainable raw materials compared to conventional ones. Hemp and organic cotton often come with a higher price tag, impacting overall production costs and pricing strategies.

Additionally, sourcing these materials consistently and in sufficient quantities can be difficult, leading to supply chain issues. Another challenge is the limited availability of advanced, eco-friendly technologies and processes within the country. While there is a growing focus on sustainability, investing in and implementing state-of-the-art machinery for eco-friendly production can be costly and require significant infrastructure changes.

“In marketing sustainable fabrics, educating consumers about the benefits and value of eco-friendly products is a challenge. Many consumers may not fully understand the advantages of sustainable fabrics or may be hesitant to pay a premium for them,” he asserted. He feels that effective branding and communication strategies to highlight the unique qualities and benefits of sustainable fabrics is the only way forward.

The current capacity is 2,50,000 meters of fabric per month.