Zünd continues its expansion of cutting systems, software tools, and automation solutions, striving to cater to productivity needs across the board—for every customer, requirement, and budget. Presenting its modular product portfolio at Drupa 2024 (Hall 9, Booth B03) under the theme “Performance across the board,” Zünd aims to underscore its commitment to meeting diverse industry demands.

In the intricate value chains of packaging and display manufacturing, print services, and advertising, digital cutting assumes pivotal significance. Zünd cutters serve as indispensable components of workflow optimization, synergizing with upstream and downstream processes to enhance productivity while ensuring high quality and error-free production.

This imperative resonates with both small-scale enterprises and large industrial operations alike.

Lars Bendixen, Segment Manager at Zünd, affirms,

“We’ve methodically expanded our portfolio to refine cutting workflows at every juncture. At Drupa 2024, we’ll unveil innovative, highly productive solutions, tailored to digitally transform production in accordance with our clients’ unique requisites. Through meticulous consultations, we delve into their specific needs, enabling us to curate precisely the right blend of solutions for a seamless and competitive production workflow. We actively support their transition to a digitalized future.”

For Zünd, paramount is the digitalization and automation of its customers’ value chains, bolstering their competitive edge. Consequently, Zünd’s cutting solutions are increasingly endowed with autonomous capabilities, aligning with the ethos of digital transformation.

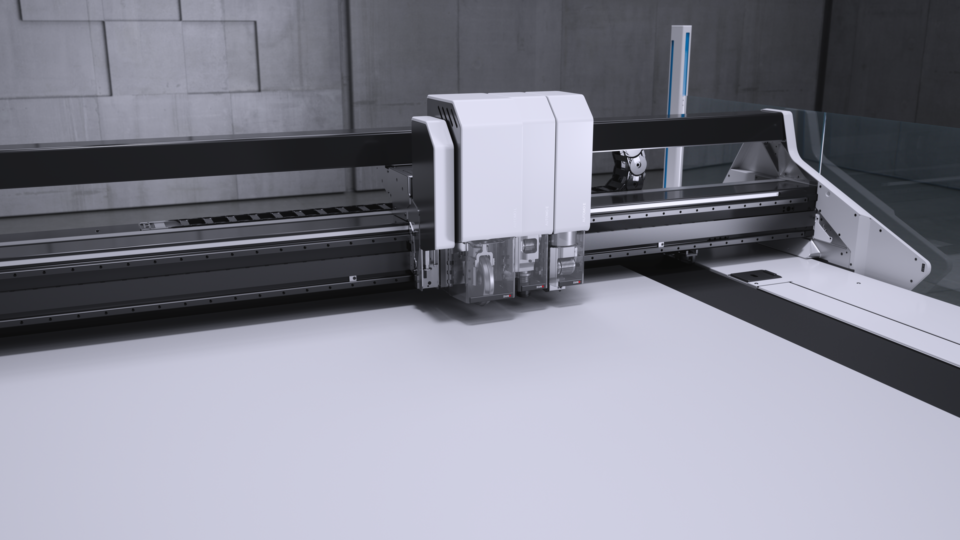

Premiering at trade shows is the Zünd Q-Line, featuring the revolutionary Board Handling System BHS180 and integrated UNDERCAM optical capturing system.

This cutting-edge solution sets benchmarks in uninterrupted industrial production, epitomizing the pinnacle of automated digital cutting. The Q-Line’s groundbreaking machine concept, paired with the BHS180, redefines performance benchmarks across multiple parameters, substantially enhancing production efficiency compared to conventional die cutting methods.

Crafted from highly stable mineral casting, the Q-Line’s substructure ensures seamless operation and optimal cutting precision, even at elevated speeds.

Carbon fiber-reinforced plastic beams imbue the machine with lightweight yet robust characteristics, facilitating precise cutting of challenging materials at peak velocities.

With the introduction of the Q-Line, Zünd’s portfolio of cutting solutions attains a zenith, encompassing all performance tiers and addressing diverse customer needs comprehensively.