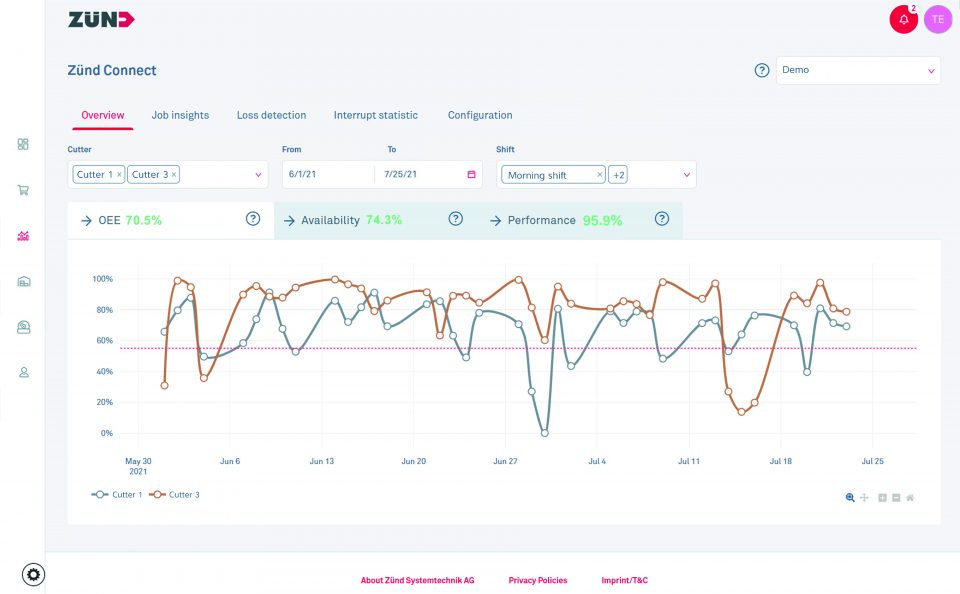

Zünd Connect compiles production data from integrated Zünd cutting systems into meaningful key performance indicators, such as cutter overall equipment effectiveness.

Zünd now offers Zünd Connect, a monitoring tool that helps the user recognise this potential and increase productivity.

Using Zünd Connect, the user can see at a glance when and, more importantly, why machine interruptions occur, how much time is spent in setup, and what the availability of each machine is the most successful companies are the ones that produce the most saleable products per hour.

High machine availability and productivity are essential for profitable cutting and finishing.

As simple as this may sound, it is no small thing in the day-to-day production environment.

The web-based monitoring tool gives the user access to cutter- performance data at a glance, any time of day. Reliable key performance indicators are available at all times to help users maximize productivity.

The system records productivity levels over a freely definable period using Zünd Cut Center – ZCC (Version ‘’’’’’3.4 or later) as data source.

Data monitoring provides information users need in order to make informed decisions.

This comprehensive overview of production data reveals connections that are often overlooked.

Zünd Connect supplies valuable key performance indio-cators for assessing how efficiently cutting systems are working.

This dashboard provides past production data and indicates, for example, fluctuations in machine utilization. The user can select various views and switch between indices for overall equipment effectiveness (OEE), availability, and capacity.

In addition, a filter function can be used to compare performance across different shifts.

Zünd Connect is available in a “Monitor” or an “Analyzer” version. As the name suggests, “Monitor” consists of a graphical display of overall equipment effectiveness and is available to all ZCC users for free.

“Analyzer”, on the other hand, makes it possible to perform subsequent analysis and pinpoint productivity losses.

“Analyzer” provides the necessary tools for the user to be able to evaluate the production process and recommend improvements.